Growth in dealer/channel revenue through structured partner engagement and performance management.

At Progility Consulting, we help companies unlock the next wave of growth through a structured, insight-led approach to Sales Acceleration. Our work spans both industrial product companies leveraging retail and channel partners, as well as B2B and B2C services businesses looking to strengthen their sales engine.

In an increasingly competitive environment, businesses face multiple barriers to sustainable sales growth and research across industry sectors highlight some important goals.

Process Optimization: Standardize processes to minimize variability, streamline workflows, improve consistency and eliminate waste.

Capacity Utilization: Optimize production schedules to maximize machine and labour efficiency. Reduce downtime through preventive maintenance and real-time monitoring.

Demand Forecasting and Planning: Leverage advanced analytics to accurately predict customer demand. Align production schedules and inventory levels with forecasts.

Streamlined Supply Chain Management: Strengthen supplier relationships to ensure timely material availability. Diversify suppliers to reduce dependency and mitigate delays.

Cross-Functional Collaboration: Foster communication between sales, operations, and logistics teams for better alignment.

Supplier Selection and Collaboration: Foster transparent communication and collaboration to build strong, long-term relationships.

Cost Management: Negotiate clear and fair pricing agreements, including volume-based discounts. Regularly review contracts to ensure alignment with market trends and cost benchmarks.

Quality Assurance: Establish rigorous quality standards and integrate them into contracts. Conduct regular audits and implement real-time monitoring to ensure compliance.

Technology Integration: Use digital platforms to track production progress and ensure transparency. Implement data-sharing systems for seamless collaboration and decision-making.

Preventive Maintenance (PM): Establish regular inspection and service schedules to address potential issues early. Use checklists and standard operating procedures to ensure consistency.

Root Cause Analysis (RCA): Investigate recurring issues to identify and eliminate the root causes of failures. Implement corrective actions to prevent the recurrence of problems.

Spare Parts Management: Maintain an optimized inventory of critical spare parts to minimize downtime. Use data analysis to predict demand and avoid overstocking or shortages.

Define Clear Quality Standards: Establish and document measurable quality benchmarks aligned with customer expectations and industry standards. Use ISO certifications and frameworks to standardize practices.

Statistical Process Control (SPC): Use real-time data and control charts to monitor process variability. Address deviations promptly to ensure consistency and prevent defects.

Supplier Quality Management: Collaborate with suppliers to ensure material quality meets specifications. Conduct regular audits and implement robust supplier qualification processes.

Customer Feedback Integration: Actively gather and analyze customer feedback to identify areas for improvement. Use insights to refine products, services, and processes.

Adopt IoT and Smart Sensors: Install IoT-enabled devices to collect real-time data on machine performance, energy consumption, and environmental conditions. Use this data for predictive maintenance, quality control, and process optimization.

Integrate Enterprise Resource Planning (ERP): Connect ERP systems with production lines for seamless data flow and coordination. Enable end-to-end visibility across procurement, inventory, and production.

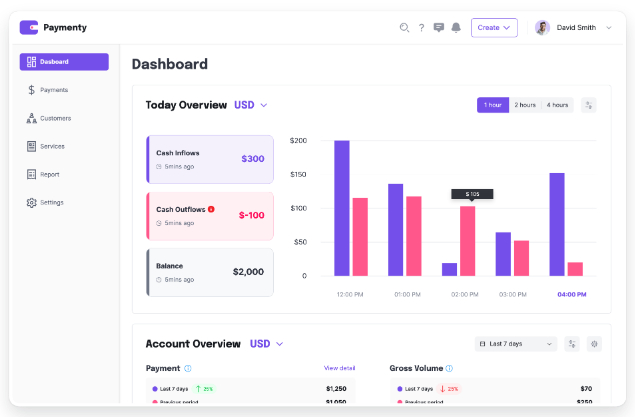

Implement Advanced Analytics and Dashboards: Use data analytics platforms to visualize KPIs, identify bottlenecks, and optimize resources. Employ dashboards for actionable insights into operations.

We start with a rapid but deep dive into your current sales engine—teams, tools, targets, and traction. We identify quick wins and root causes for underperformance across your pipeline.

We conduct a granular market mapping exercise to identify high-potential regions, districts, or customer clusters. This helps sharpen your focus and ensure resource allocation is aligned with opportunity.

This ensures your sales team is spending time and effort where it matters most.

We define/refine:

We map the customer journey and sales stages, remove handoff friction, and introduce pipeline management discipline with clear KPIs and win/loss analytics.

We enhance skills, develop customized sales playbooks, and design performance-linked incentive structures. For field teams, we work on improving pitch, productivity, and closure rates.

We help deploy or optimize CRM systems, integrate lead management tools, and implement dashboards for visibility and control—empowering leadership with data-driven insights.

We stay embedded to support rollout, run sales war rooms, track interventions, and drive results. Clients often see impact within 8–12 weeks.

Increase in lead-to-order conversion rates through funnel optimization

Productivity improvement in sales teams with better territory planning and time utilization

Reduction in sales cycle times in B2B services through revamped pitch and faster decisioning

Growth in dealer/channel revenue through structured partner engagement and performance management.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Discover a premier digital consumer brand offering comprehensive travel information and inspiration. With a rich heritage of over 30 years in print and two decades online, this platform provides accurate content on top global destinations. From cities and airports to resorts and attractions, our dedicated editorial team updates the portal daily, attracting millions of unique users monthly.

Subscribe to our channel

About

FAQs

DESTINATIONS

Webinars

News

COMMUNITY

Vlogs

Events

Podcasts

SHOP

Text Here